The difference between carbon steel and galvanized steel

Carbon steel and galvanized steel differ in the following four aspects:

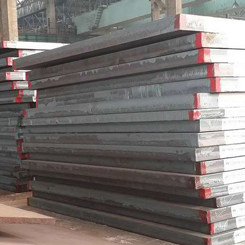

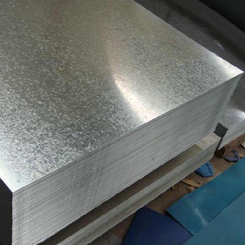

Raw materials: Galvanized steel is made by galvanizing on the basis of ordinary steel. Its outer layer is zinc. The zinc layer can effectively protect the steel material from corrosion and oxidation, and has good anti-corrosion and wear resistance. Carbon steel is ordinary steel composed of iron and carbon and contains higher carbon elements, usually between 0.06%-1.5%.

Features: Galvanized steel has superior corrosion resistance and beautiful appearance, but problems such as coating peeling and deformation may occur. Carbon steel has high strength and rigidity, but is susceptible to corrosion and fatigue.

Fields of use: Galvanized steel is mainly used in places where corrosion resistance and aesthetics are required, such as building structures and automobile parts. Carbon steel is suitable for various fields, especially mechanical parts and structural parts that require high strength and durability.

Production process: Galvanized steel needs to be hot-dip galvanized during the production process, that is, ordinary steel is immersed in high-temperature molten zinc liquid for galvanizing. During this process, the steel forms a zinc-iron alloy layer that is highly corrosion-resistant and decorative. Carbon steel does not need to be hot-dip galvanized and is usually produced using various processes such as high-frequency induction heating and converter refining.

Generally speaking, there are differences between carbon steel and galvanized steel in terms of raw materials, characteristics, application fields and production processes. It is necessary to choose the appropriate material according to the specific use needs and actual conditions.

Raw materials: Galvanized steel is made by galvanizing on the basis of ordinary steel. Its outer layer is zinc. The zinc layer can effectively protect the steel material from corrosion and oxidation, and has good anti-corrosion and wear resistance. Carbon steel is ordinary steel composed of iron and carbon and contains higher carbon elements, usually between 0.06%-1.5%.

Features: Galvanized steel has superior corrosion resistance and beautiful appearance, but problems such as coating peeling and deformation may occur. Carbon steel has high strength and rigidity, but is susceptible to corrosion and fatigue.

Fields of use: Galvanized steel is mainly used in places where corrosion resistance and aesthetics are required, such as building structures and automobile parts. Carbon steel is suitable for various fields, especially mechanical parts and structural parts that require high strength and durability.

Production process: Galvanized steel needs to be hot-dip galvanized during the production process, that is, ordinary steel is immersed in high-temperature molten zinc liquid for galvanizing. During this process, the steel forms a zinc-iron alloy layer that is highly corrosion-resistant and decorative. Carbon steel does not need to be hot-dip galvanized and is usually produced using various processes such as high-frequency induction heating and converter refining.

Generally speaking, there are differences between carbon steel and galvanized steel in terms of raw materials, characteristics, application fields and production processes. It is necessary to choose the appropriate material according to the specific use needs and actual conditions.

Related Products

Factory Introduction

Choose the right stainless steel material according to your needs

316N Stainless Steel

Contact Us