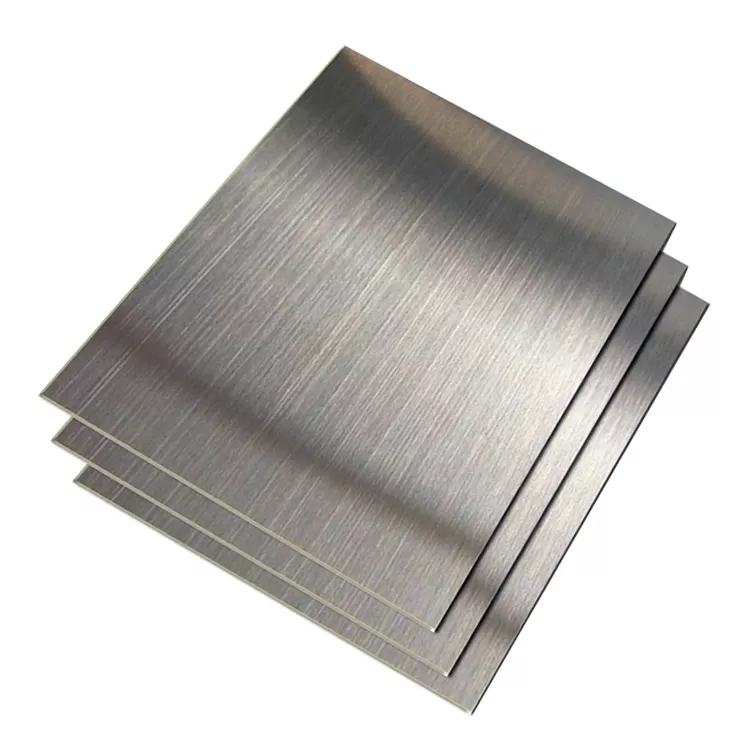

316N Stainless Steel

Abstract: 316N stainless steel, an enhanced variant of the widely-used 316 stainless steel, is gaining attention for its superior mechanical properties and corrosion resistance. This article aims to explore the unique characteristics, advantages, and potential applications of 316N stainless steel, providing valuable insights for engineers, designers, and manufacturers seeking high-performance materials for challenging environments.

Introduction:

In modern engineering, the demand for materials capable of withstanding harsh conditions while maintaining optimal performance has led to the development of advanced alloys. Among these, 316N stainless steel stands out as a promising solution, offering improved mechanical strength and corrosion resistance compared to traditional stainless steel grades. This article delves into the distinctive features and applications of 316N stainless steel, shedding light on its suitability for various industrial sectors.

Characteristics of 316N Stainless Steel:

Enhanced Strength: 316N stainless steel exhibits higher tensile and yield strength compared to standard 316 stainless steel, making it suitable for applications requiring superior mechanical properties.

Improved Corrosion Resistance: With its nitrogen content, 316N stainless steel offers enhanced resistance to pitting and crevice corrosion in chloride-rich environments, expanding its usability in marine and chemical processing applications.

Heat Resistance: The alloy's composition provides good resistance to elevated temperatures, allowing it to maintain structural integrity in high-temperature applications.

Applications of 316N Stainless Steel:

Marine and Offshore Structures: Due to its superior corrosion resistance, 316N stainless steel is well-suited for marine equipment, offshore platforms, and seawater piping systems, where exposure to corrosive environments is common.

Chemical Processing: In chemical processing plants, 316N stainless steel finds application in reactors, storage tanks, and pipelines handling aggressive chemicals, thanks to its resistance to corrosion and high mechanical strength.

Aerospace and Automotive Components: The alloy's combination of strength and corrosion resistance makes it suitable for aerospace components, automotive exhaust systems, and other high-performance applications requiring reliability under demanding conditions.

Conclusion:

316N stainless steel emerges as a promising material offering a balance of strength, corrosion resistance, and heat resistance, making it suitable for a wide range of demanding applications. Engineers and manufacturers seeking materials capable of meeting stringent performance requirements should consider the unique advantages of 316N stainless steel in their designs and applications.

By highlighting the distinctive properties and potential applications of 316N stainless steel, this article aims to facilitate informed decision-making among industry professionals, driving the adoption of advanced materials for enhanced performance and reliability in challenging environments.

Related Products

Contact Us