Polished Finish 420 Stainless Steel Coil

420 Stainless steel coil using condition,the use of 420 steel quenched and tempered state (hardness 48-54HRC), in order to meet the number of long-term work or product of 1 million or more life requirements, more suitable methods should be done using quenching and low temperature tempering treatment. The quenching is first heated to 1000-1050 DEG C heat preservation time (30 /25mm calculation), and then quenched into oil cooling to 50-100 DEG C and immediately tempering, to prevent cracking.Tempering at 200 degrees (at least 4 hours) can reach more than 48HRC, with a better polishing performance and better corrosion resistance.

For the polished finish condition,420stainless steel coil do tempering at 200 degrees (at least 4 hours) can reach more than 48HRC, with a better polishing performance and better corrosion resistance.

420 Stainless steel coil with the chemical composition as the following,C Si Cr Mn Mo V S 0.40 0.80 13.50 0.50 0.60 0.20 0.03 420 of the carbon content of the steel coil is less than 0.35, after heat treatment, the hardness of the resulting hrc52-55, and resistance to damage and other aspects of the performance is not very outstanding. Because of the easy cutting and grinding, so it is suitable for mass production of the 420 steel plant system tool, also because of low carbon content and rust resistance is extremely strong, so it is also an ideal tool for steel production of diving.

Surface description of the 420 stainless steel coil,after heat treatment and pickling treatment of NO.1,it is hot rolling. 2B finish after cold rolling, heat treatment, pickling or similar treatment, and finally get the appropriate gloss surface.

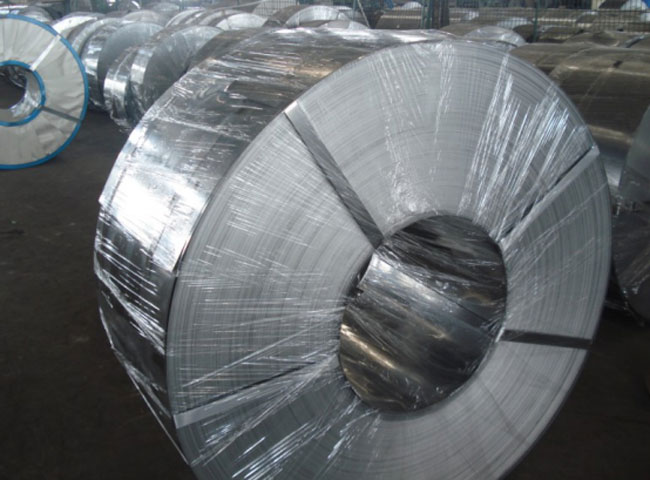

420 stainless steel coil specification,420 stainless steel hot rolled coil thickness: 1.5-14mm width 1000 or 1219 or 1500 or 1800 or 2000 (including flash); 420 cold-rolled stainless steel: thickness 0.3-3.0 width of 1000 or 1219 or 1500 (including flash).

Related Products