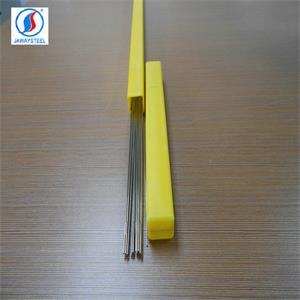

316L Stainless Steel TIG Welding Wire

Jaway steel is major manufacturing specialized in stainless steel wih high quality and best price! Which can be widely used in bicycle fittings, kitchen and sanitation tools, goods shelf, pet cages, gill racks, decorative handles and baskets, food and medical machinery accesses, etc.

316L Stainless Steel TIG Welding Wire :

Tungsten Inert Gas Welding, also known as non-melting inert gas shielded arc welding. TIG welding is the most commonly used welding method, whether it is manual welding or automatic welding of 0.5 to 4.0 mm thick stainless steel. The method of filling and filling with TIG is often used for the bottom welding of pressure vessels, because the airtightness of TIG welding can better reduce the pores of the welds during welding of pressure vessels. The heat source of TIG welding is a direct current arc, and the working voltage is 10 to 95 volts, but the current can reach 600 amps. The correct connection of the welder is that the workpiece is connected to the positive pole of the power supply, and the tungsten pole in the torch acts as the negative pole. The inert gas is typically argon.

316L Stainless Steel TIG Welding Wire welding process:

The inert gas is fed through the torch to form a shield around the arc and on the weld pool. To increase the heat input, typically 5% hydrogen is added to the argon. However, when ferritic stainless steel is welded, it cannot be hydrogenated in argon. Gas consumption is about 3 to 8 liters per minute. In addition to the inert gas being blown from the torch during the welding process, it is preferable to blow the gas for protecting the back side of the weld from the weld.

If necessary, the weld pool can be filled with the same welding wire as the austenitic material to be welded. When welding ferritic stainless steel, 316 type packing is usually used.

316L Stainless Steel TIG Welding Wire Principles and advantages:

Gas shielded welding is an arc welding method using an applied gas as a protective medium. The advantage is that the arc and the molten pool have good visibility and convenient operation; there is no slag or little slag, and there is no need to clean the slag after welding. However, special wind protection measures are required when working outdoors.

Gas shielded welding can be classified into non-melting pole (tungsten) gas shielded welding and gas metal arc welding according to whether the electrode is melted during the welding process. The former includes tungsten inert gas shielded welding, plasma arc welding and atomic hydrogen welding. Atomic hydrogen welding is currently rarely used in production. Tungsten inert gas shielded welding is referred to as TIG (Tungsten Inert Gas Welding).

It is a welding method that uses an arc heat generated between a tungsten electrode and a workpiece to melt the base material and fill the wire (if a filler wire is used) under the protection of an inert gas. During welding, the shielding gas is continuously ejected from the nozzle of the welding torch, and a gas protective layer is formed around the arc to block the air to prevent harmful effects on the tungsten electrode, the molten pool and the adjacent heat-affected zone, thereby obtaining a high-quality weld.

The shielding gas may be a mixed gas of argon, helium or argon. In special applications, a small amount of hydrogen can be added. The use of argon gas as the shielding gas for tungsten argon arc welding, and the use of helium gas for tungsten arc welding, due to the high price of helium gas, the application of tungsten argon arc welding in industry is much wider than that of helium arc welding.

This chapter introduces tungsten inert gas welding as a typical example of tungsten argon arc welding. In some places, the unique properties of helium and tungsten arc welding are also explained.

If you want to get more information about 316L Stainless Steel TIG Welding Wire pls contact us-Jaway Steel-via 819@jawaysteel.com!

Related Products